Welding and Fabrication

Kaler Engineering are proud to offer a wide range of structural steelwork products and from temporary works, steel frame buildings, builders beams and all structural elements.

Kaler Engineering Ltd are CE Marked to execution level 2 and we ensure compliance and the manufacture of best quality products to BS EN 1090:1+2. With over 50 ton of stock we can react to our client's needs and offer a 24-48-hour turnaround, just in time for tight timescales.

A combination of skilled workforce, in house design team and in-house laser machine and CNC workshop we can offer a complete, one-stop-shop package. Other services including drilling, welding, punching and folding.

Our in-house installation teams all hold valid CSCS cards and SSSTS / SMSTS for supervisors /managers. Our skilled teams also hold valid IPAF and PASMA tickets all necessary to carry out a fast and safe installation. All our installations are in accordance with our CE Mark execution level 2.

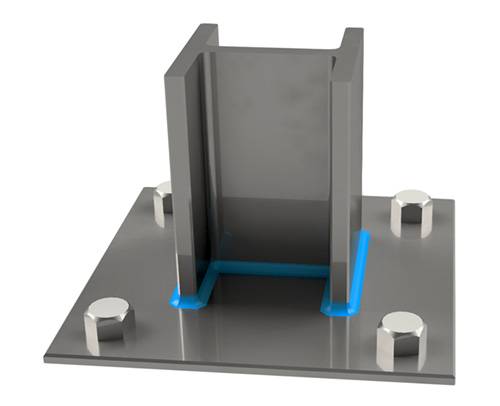

Base Plate Connection

End Plate Connection

Moment Connection

Cleat Connection

Dogleg Connection

Gusset

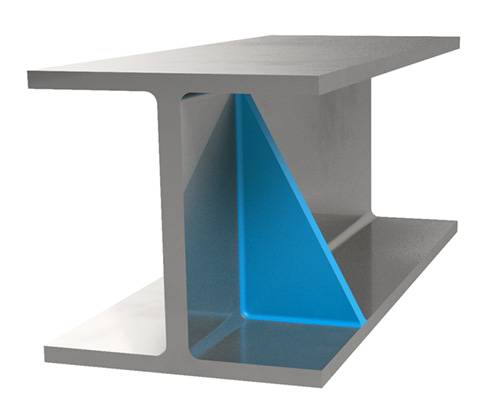

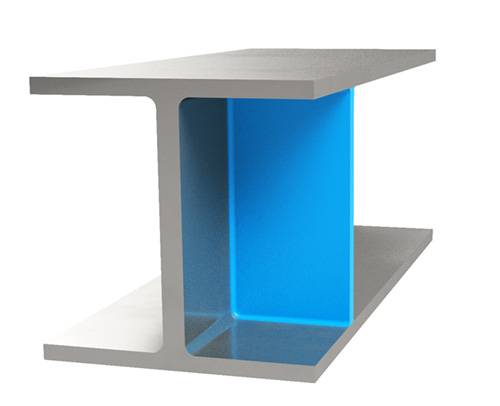

Stiffener

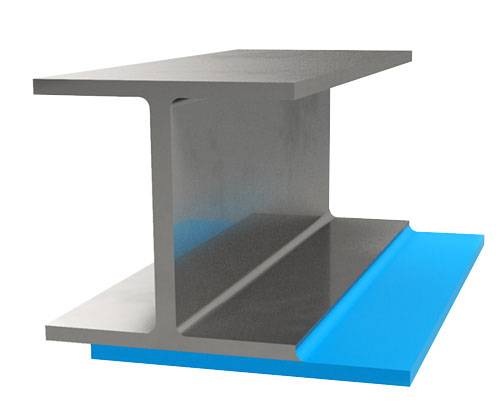

Bottom Plate

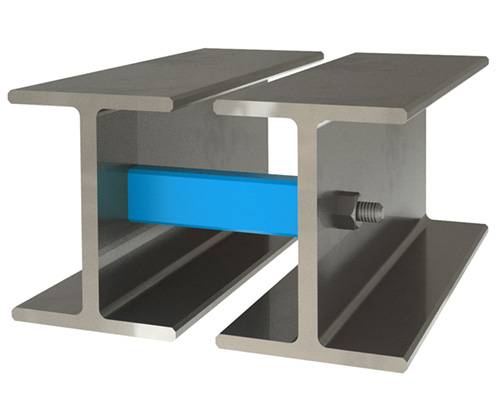

Beam Spacers

PFC Spacer

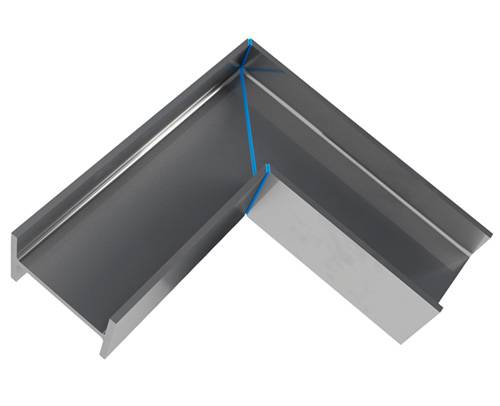

Crank Connection

90 Degree Kink Connection

Splice Connection A1

Splice Connection A2

Splice Connection A3